In this tutorial, we’ll show you how to drive a bipolar stepper motor using a DRV8825 driver. This tutorial is compatible with stepper motor drivers commonly used in digital milling or 3D printer projects (DRV8825, SilentStepStick, etc.).

Hardware

- Arduino UNO

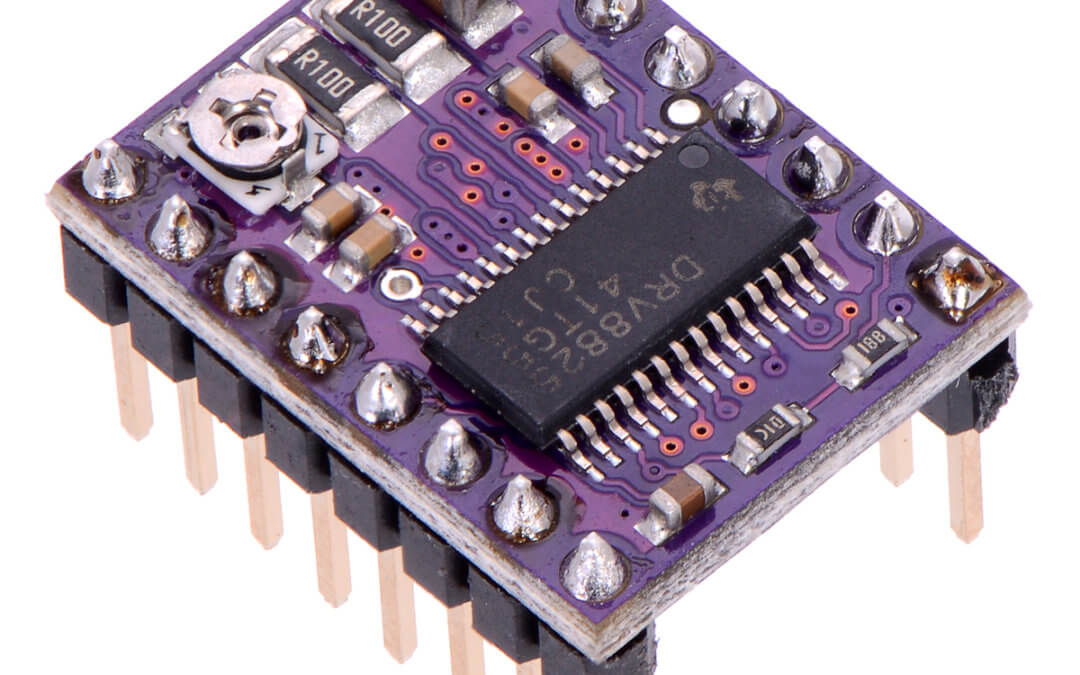

- Stepper driver DRV8825 (or A4988 or SilentStepStick)

- USB A male to USB B male cable

Operating principle

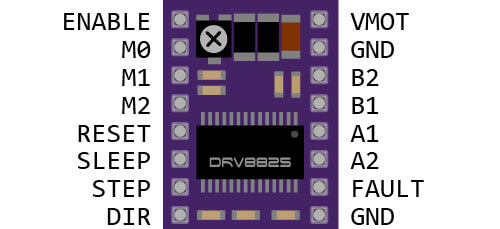

Stepper motor drivers enable efficient motor control using just two control signals, STEP and DIR. The number of pulses sent to the driver corresponds to the number of steps taken, the pulse frequency to the motor speed, and the dir signal to the direction of motor rotation. The DRV8825 module takes care of sending the sequence to the two motor coils according to the commands received as input.

Technical specifications DRV8825

| M0 | M1 | M2 | Microstep resolution |

|---|---|---|---|

| Low | Low | Low | Full step |

| High | Low | Low | 1/2 step |

| Low | High | Low | 1/4 step |

| High | High | Low | 1/8 step |

| Low | Low | High | 1/16 step |

| High | Low | High | 1/32 step |

| Low | High | High | 1/32 step |

| High | High | High | 1/32 step |

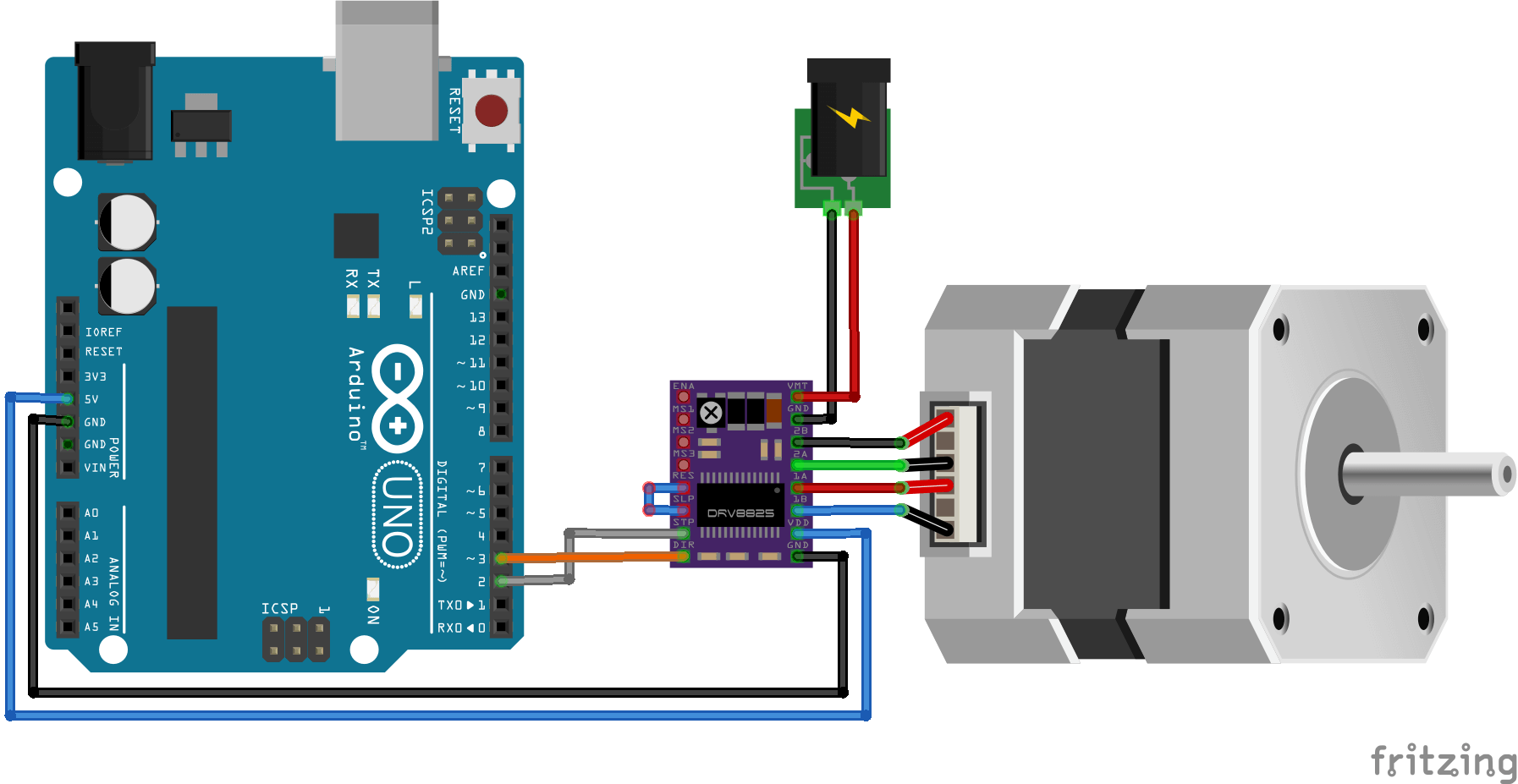

Diagram

Before connecting your motor to the driver, please set the current limiter correctly. This requires:

- supply the Arduino and Shield with Motor voltage.

- Then place a voltmeter between the potentiometer and GND.

- Turn the potentiometer with a screwdriver until you obtain the value that follows the following rule.

MaxCurrent=Vref x 2

For example:

If the current value is 1A, the value displayed on the multimeter must be equal to 0.5V.

MaxCurrent=1.0A –> Vref = 0.5V

It is possible to modify the driver step resolution for greater precision. This configuration is defined by setting pins M0, M1 and M2 to HIGH or LOW according to the following logic table.

| M0 | M1 | M2 | Microstep resolution |

|---|---|---|---|

| Low | Low | Low | Full step |

| High | Low | Low | 1/2 step |

| Low | High | Low | 1/4 step |

| High | High | Low | 1/8 step |

| Low | Low | High | 1/16 step |

| High | Low | High | 1/32 step |

| Low | High | High | 1/32 step |

| High | High | High | 1/32 step |

Code

To drive the stepper motor driver, we simply send a HIGH or LOW state to the DIR pin and a pulse to the STEP pin.

const int stepPin = 2; const int dirPin = 3; const int stepsPerRev=200; int pulseWidthMicros = 100; // microseconds int millisBtwnSteps = 1000; void setup() { Serial.begin(9600); pinMode(stepPin, OUTPUT); pinMode(dirPin, OUTPUT); Serial.println(F("A4988 Initialized")); } void loop() { Serial.println(F("Running clockwise")); digitalWrite(dirPin, HIGH); // Enables the motor to move in a particular direction // Makes 200 pulses for making one full cycle rotation for (int i = 0; i < stepsPerRev; i++) { digitalWrite(stepPin, HIGH); delayMicroseconds(pulseWidthMicros); digitalWrite(stepPin, LOW); delayMicroseconds(millisBtwnSteps); } delay(1000); // One second delay Serial.println(F("Running counter-clockwise")); digitalWrite(dirPin, LOW); //Changes the rotations direction // Makes 400 pulses for making two full cycle rotation for (int i = 0; i < 2*stepsPerRev; i++) { digitalWrite(stepPin, HIGH); delayMicroseconds(pulseWidthMicros); digitalWrite(stepPin, LOW); delayMicroseconds(millisBtwnSteps); } delay(1000); }

For more functionality, you can use the AccelStepper.h library.

Applications

- Stepper motor control

- Controlling multiple motors with a CNC Shield